Product

Parts Localized

Parts Localized

| Localized Parts | Equipment | Process | OEM P/N |

|---|---|---|---|

|

TCP |

LAM 300mm FLEX, FLEX45, KIYO |

Etch |

853-017892-201(7.1KW) |

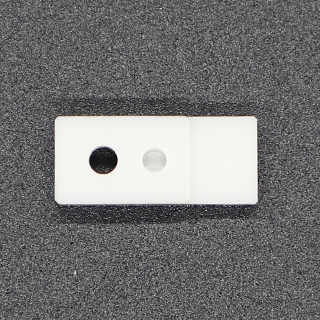

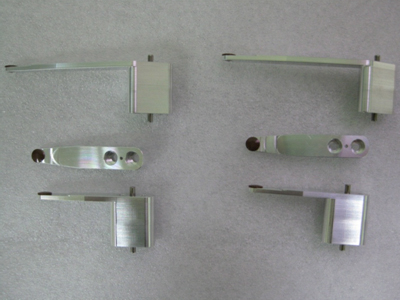

HIGH GAP HANGER

SMI : 713-037072-003

Low GAP HANGER

SMI : 713-037069-003

NUT HANGER

SMI : 839-039317-003

PAD WASHER SPACER

SMI : 713-034965-001

D-WASHER

SMI : 713-034964-001

SLEEVE

SMI : 713-027299-002 SYSTA : 713-027299-002

WASHER FLAT Confiment Ring

713-040539-001(Z)| Classification | Description |

|---|---|

|

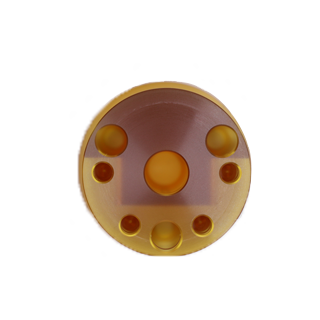

Product |

LAM Zirconia Part |

|

Material |

PEEK → Zirconia |

|

Application |

LAM ETCH |

|

REV |

Change the material from PEEK to ZIRCONIA |

|

Main Supply Contractor |

SK-Hynix, UMC, Micron, etc |

|

Product description |

PEEK, the original part in the SKHYNIX ETCH LAM facility, was changed to Zirconia to extend the use cycle and improve some items to be used semi-permanently |

CONDUCTOR, BIAS

300MM, HDPCVD, ULTIMA

(I)SKT, PLASMA SNSR

715-038611-002

(A)QTZ PIN_PIN, ALIGN, UPR

ELCTD, 300MM_

ASSY, STUD, SOCKET.300MM;

P/N : 839-070842-004

I*)ESC WATER

MANIFOLD(ULTEM)_ULTIMA

ACCESSORY_FACE SEAL

GAS INJCTR(2300 POLY)

(I)LIFT PIN HOLDER HOUSING

LPHH-0101

(I)LIFT PIN HOLDER BASE

LPHB-0101| Description | Application | Vendor P/N | SAP N/O | Business Start | Installation |

|---|---|---|---|---|---|

|

300mm Robot Blade |

YASKAWA, BROOKS KAWASAKI, PSK |

|

|

Since 2011 |

SK Hynix |

|

Background & Development |

|||||

|

1. Cost reduction and delivery time improvement compared to OEM parts |

|||||

KAWASAKI OLD TYPE

KAWASAKI NEW TYPE

PSK SUPRA3 BLADE

YASKAWA BLADE

Flatness Test w/o wafer

Flatness Test w/o wafer

Sensor Test

Pad standard test

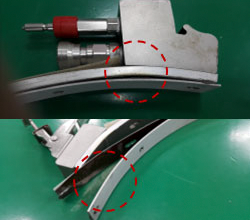

| Part Number | Product name | Equipment | Improvement |

|---|---|---|---|

|

678-031432-004 |

Temerature Control Ring |

LAM KIYO Poly KIYO45 |

Arcing and durability improvement |

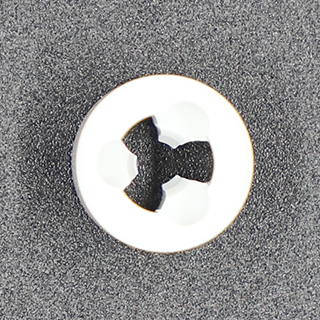

| Before | After | Details |

|---|---|---|

|

SUS Pattern Heater Film Pattern Heater causes frequent arcing between aluminum plates : the main cause of arcing is due to the gaps made by thermal expansion between materials, frequent operation, resin (silicon or epoxy) falling off, etc |

Ni_Cr Wire Heater Ni_Cr wire is inserted into the aluminum plate body to produce a structure that does not generate arcing even if gaps occur. In addition, a heater with a heating wire, which is more durable than a pattern heater, is used. |

Reduces arcing, prevents film heater fail, improves heater life time, improves durability, etc |

| Equipment | Process | OEM P/N |

|---|---|---|

|

LAM FLEX 300mm |

ETCH |

715-009191-001 |