Product

Ozone Water Supply System

Ozone Water Supply System

Cleaning process of semiconductor, display, OLED and other high-tech industries

Substitute for strong acid materials used in PR strip, etching process, etc

BOD, COD, SS etc purification treatment of industrial sewage/wastewater

Disinfection and sterilization of medical equipment, food production facilities

It can be used as a substitute for strong acids such as H2SO4, HF, NH03, and does not generate harmful substances to the environment

It can be used in various fields depending on the concentration and has high efficiency

Use Ozone Water Only and DHF Mix for Semiconductor Fine Pattern Organic and Inorganic Cleaning

Application: Semiconductor, Display, Pre-cleaning in OLED process, Post-cleaning

Generated concentration : 10 ~ 190 ppm

Used flow rate : 20 ~ 140 LPM

Low power high concentration ozone gas generator

Compact size and PLC automatic control

Composed of PFA acid-resistant material in all sections, zero corrosion and foreign substances

Able to provide a rapid service response with an in-house production of core parts

Safety design for power and gas use to block emissions and configure interlock

Additional equipment : Ozone destructor, ozone water purification equipment for after using

Patent application : 6 cases including 10-20948230000, 10-21028110000, etc.

| Unit | Detail | Connection | ETC | |

|---|---|---|---|---|

| Dimensions |

850 x 789 x 1789 mm |

- |

- |

|

| Power |

Supply |

208V 50/60Hz 60A 3phases |

4P 60A terminal block |

- |

| DI Water |

Flow rate |

30 l/min |

1" PVDF ball V/V union |

|

|

Pressure |

> 3.0 bar |

|

||

|

Temperature |

< 24℃ |

|

||

|

PH |

≤ 7 |

|

||

| Cooling Water |

Flow rate |

8 l/min |

3/8”Swagelok |

|

|

Pressure |

>1.5 bar, <5.0 bar |

|

||

|

Temperature |

< 23℃ |

|

||

| CDA |

Flow rate |

40 l/min |

1/4” Swagelok |

|

|

Pressure |

4.0~6.0 bar |

|

||

|

Connection |

1/4” VCR |

|

||

| O2 |

Purity |

> 99.9% |

1/4” VCR Male Union |

|

|

Flow rate |

10~20 l/min |

|

||

|

Pressure |

4.0~6.5 bar |

|

||

| N2 |

Purity |

> 99.9% |

1/4” VCR Male Union |

|

|

Flow rate |

10~20 cc/min |

|

||

|

Pressure |

4.0~6.5 bar |

|

||

| CO2 |

Purity |

> 99.9% |

1/4” VCR Male Union |

|

|

Flow rate |

1 l/min |

|

||

|

Pressure |

4.0~6.5 bar |

|

||

| Exhaust |

Pressure |

> 400 Pa |

150A SUS Flange | Manufacture and deliver relative flanges in accordance with standard usage specifications |

| O3 DIW Out |

O3 DI Water |

30 l/min |

1" piller S300(Double piping 40A) |

|

|

O3 Return |

10~25 l/min |

3/4" piller S300(Double piping 40A) |

Models with O3 water recovery(Limpio-S30R) |

|

|

O3 Drain |

7 l/min |

1/2" piller S300(Double piping 40A) |

||

| Drain |

Vat Drain |

- |

1/2" Swagelok |

|

|

Dike Vat Drain |

- |

15A PVC Ball V/V 1/2" PMAIL |

|

|

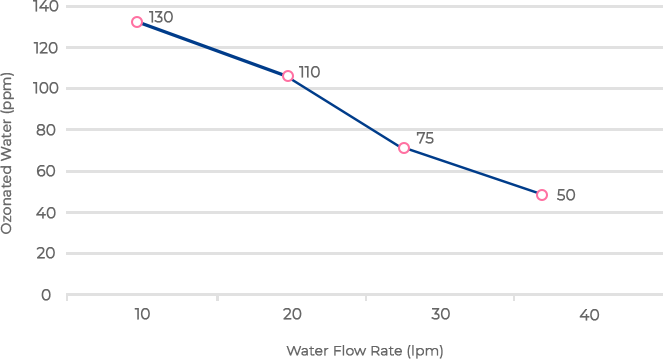

| Water Flow Rate | Ozonated Water | N2 | O2 | Co2 | Cooling Water | DI Water |

|---|---|---|---|---|---|---|

10 LPM |

130 ppm |

10 sccm |

10 LPM |

0.8 LPM |

17℃ |

23℃ |

20 LPM |

110 ppm |

10 sccm |

10 LPM |

0.8 LPM |

17℃ |

23℃ |

30 LPM |

75 ppm |

10 sccm |

10 LPM |

0.8 LPM |

17℃ |

23℃ |

40 LPM |

50 ppm |

10 sccm |

10 LPM |

0.8 LPM |

17℃ |

23℃ |